Lubrication

Tribology is the science of friction, lubrication and wear and encompasses how interacting surfaces and other tribo-elements behave in relative motion in natural and artificial systems. Lubrication is a branch of tribology which refers to a principle to reduce friction and wear by introducing a lubricant between interacting surfaces in relative motion. Generally, the lubricant may be a fluid or solid and the degree of its extent ranges from boundary lubrication to a fully established lubricant film. The different lubrication regimes shall be explained with the help of the Stribek curve, depicted below. It schematically shows the transition of the lubrication condition along with the change of the frictional coefficient with respect to increasing relative sliding velocity of the contacting surfaces. Our research in this field covers the entire lubrication regimes.

Most of the application areas in the lubrication field are multi-disciplinary in nature combining aspects, e.g., from solid mechanics to tribology and further to hydrodynamics and biomechanics. Some of the interesting tribology research fields are as follows:

- Biotribology studies friction, wear and lubrication in biological systems. The field is gaining importance as human lifetime expectancy increases. Human hip and knee joints are typical biotribology systems.

- Computational tribology aims to model the behavior of tribological systems through multiphysics simulations, combining disciplines such as contact mechanics, fracture mechanics and computational fluid dynamics.

At our institute we have developed a computational model to simulate the lubricated contact problem from boundary lubrication to full film lubrication in a continuous way.

The example below illustrates the application of the Lubricated Contact Model to a fully coupled soft lubricated contact problem.

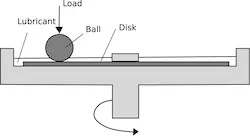

Ball-on-Disk Tribometer Benchmark example

The setup corresponds to the well-known ball-on-disk tribometer studied experimentally in the literature, which therein, an elastomeric ball is placed in a grip and is loaded by a normal force against a rotating rigid flat disk. The setup allows testing of steady-state lubrication in pure sliding only, and the sliding speed is adjusted by changing the angular speed of the supporting disk and the radial position of the ball.

Two-elastic bodies example

As an extension of the Tribometer benchmark example, we have computed the same configuration but with elastic disk, representing two-elastic bodies setup.