Combustion Instabilities in Aero Engines with Air-Staging (RQL)

Supervisor | Subject |

|---|---|

Editor | Cooperation/Funding |

| Prof. Dr.-Ing. Thomas Sattelmayer | RQL combustion chamber, thermoacoustic bahavior of rich and lean zone independently, kerosine flames, thermoacoustic behavior of self-ignition jet-in-cross-flow flames |

| Martin March, Dipl.-Ing.; Julian Renner, M.Sc. | This project is funded by the BMWi, whose support is gratefully acknowledged. |

Motivation

Improved eco efficiency of commercial flights can be achieved by further development of aero engine combustion chamber technology towards lower pollution and noise emissions. This can be accomplished by simultaneously increasing process pressure and turbine inlet temperatures, thus lowering fuel consumption and carbon dioxide emissions. RQL (rich-quench-lean) combustion is the leading technology in the sector of aero engine combustion chambers, a basic sketch of the concept is shown in Fig. 1. Combustion under rich conditions is followed by a quick quench of dilution air to reach the lean regime. Benefits are the lower flame temperatures due to high equivalence ratios and consequently thermal NOx is reduced. Additionally, a defined temperature profile for the first turbine stage is designed to reduce the cooling requirement of the first guide vanes. A key element of emission reduction is the avoidance of combustion instabilities which is becoming an increasing challenge. As a result of constructive interference between pressure oscillations of an acoustic field and heat release fluctuations of the combustion process, so called thermoacoustic instabilities arise which lead to high mechanical and thermal stresses which must be reduced due to engine damage and failure. In recent years, considerable progress has been made in this field for premixed combustion of natural gas, which dominates stationary gas-turbine combustion technology.

Bigger gaps currently occur in the rich-lean technology. Reducing these, while focusing on low frequency thermoacoustic instabilities (i.e. Rumble phenomena) motivates the project objectives: quantification of the wave dynamics in air-staged aero engines with rich-lean combustion chambers. To achieve this, an entirely new test rig is being constructed at the chair.

Experimental Setup

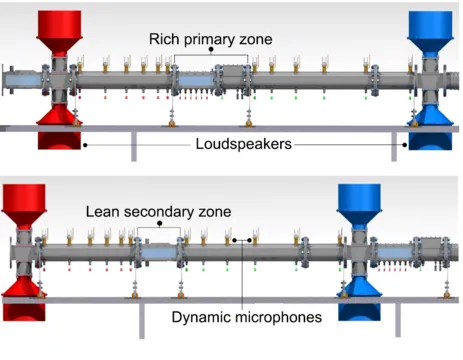

The experimental approach is to separate the rich primary zone from the lean burn out zone. Allowing experimental investigation of the two combustion zones independently from each other and subsequent development of thermoacoustic models. The modular test-rig design allows the re-use of parts and measurement techniques for the separated combustion chambers. Fig. 2 demonstrates two setup options of the test rig. The investigation of the primary and secondary combustion chamber is focused on the low frequency range (f=0 - 800 [Hz]) and consequently equivalence ratio fluctuations and entropy waves. The acoustic excitation is realized with a speaker unit consisting of two 12" loudspeakers, installed up- and downstream of the combustion zones. In the rich primary zone the complexity of the combustion will be gradually increased: starting from a premixed methane-flame to a non-premixed kerosene-flame, based on atomization and evaporation, rich combustion, comparable to real aero-engines is achieved. In addition to the acoustic excitation of the main hot gases from up- and downstream, the dilution air will also be excited. This makes the setup significantly more complex and leads to an acoustical four-port system.

Measurement Techniques

Focusing on the thermoacoustic behavior of the two combustion chambers the test rig is equipped with multiple high resolution microphones. Using the multi-microphone-method, one is able to reconstruct the acoustic waves traveling up- and downstream in the system. Characterizing the transfer behavior of the considered combustion chambers, it is mandatory to measure up- and downstream of the system. With respect to the high temperatures and reactive exhaust gases the microphones need to be water cooled and purged with nitrogen to avoid ignition spots. Quartzglas windows on the sidewalls of each chamber allow optical access to the combustion where OH* and CH* chemiluminescence measurements can detect heat release and equivalence ratio fluctuations over a wide operation range.